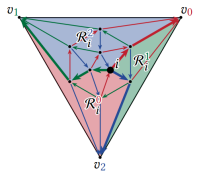

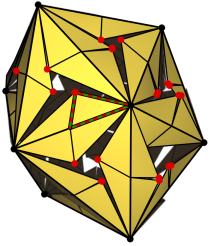

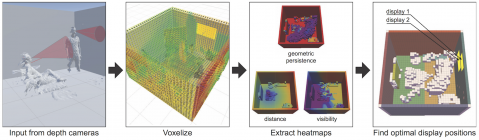

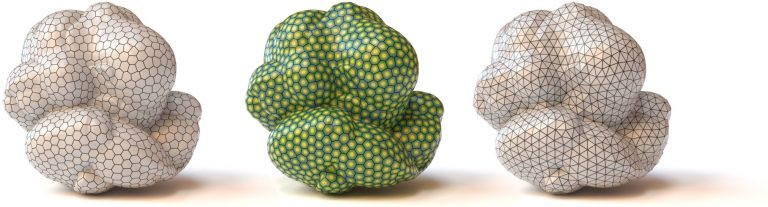

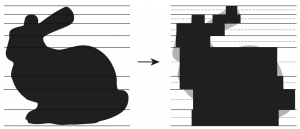

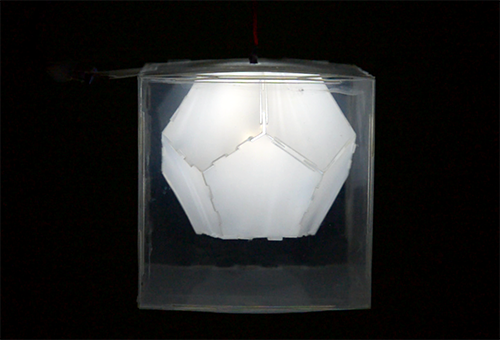

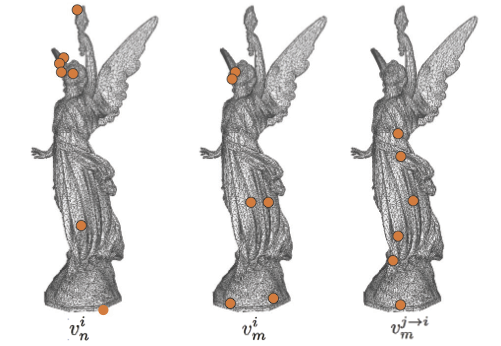

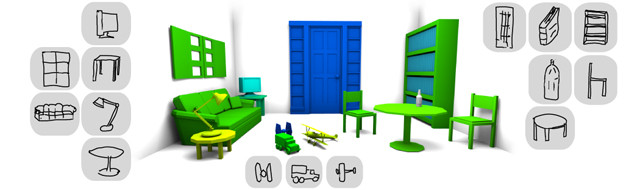

Most additive manufacturing technologies work by layering, i.e. slicing the shape and then generating each slice independently. This introduces an anisotropy into the process, often as different accuracies in the tangential and normal directions, but also in terms of other parameters such as build speed or tensile strength and strain. We model this as an anisotropic cubic element. Our approach then finds a compromise between modeling each part of the shape individually in the best possible direction and using one direction for the whole shape part. In particular, we compute an orthogonal basis and consider only the three basis vectors as slice normals (i.e. fabrication directions). Then we optimize a decomposition of the shape along this basis so that each part can be consistently sliced along one of the basis vectors.

In simulation, we show that this approach is superior to slicing the whole shape in one direction, only. It also has clear benefits if the shape is larger than the build volume of the available equipment.